Profitable robots

Using robots that perform these operations ensures quality and increases flexibility, as it is easy to reuse robots and equipment for future items, which enables and facilitates investment.

In the automotive sector in particular, it is common to use ultrasound welding for joining items. This is a quick and “clean” method that leaves no residue.

Using robots that perform these operations ensures quality and increases flexibility, as it is easy to reuse robots and equipment for future items, which enables and facilitates investment.

Using laser cutting together with robots offers the opportunity to produce an infinite number of item variations, even though the basic item is produced from a single mold! This offers major savings compared to producing individual molds for each of the versions.

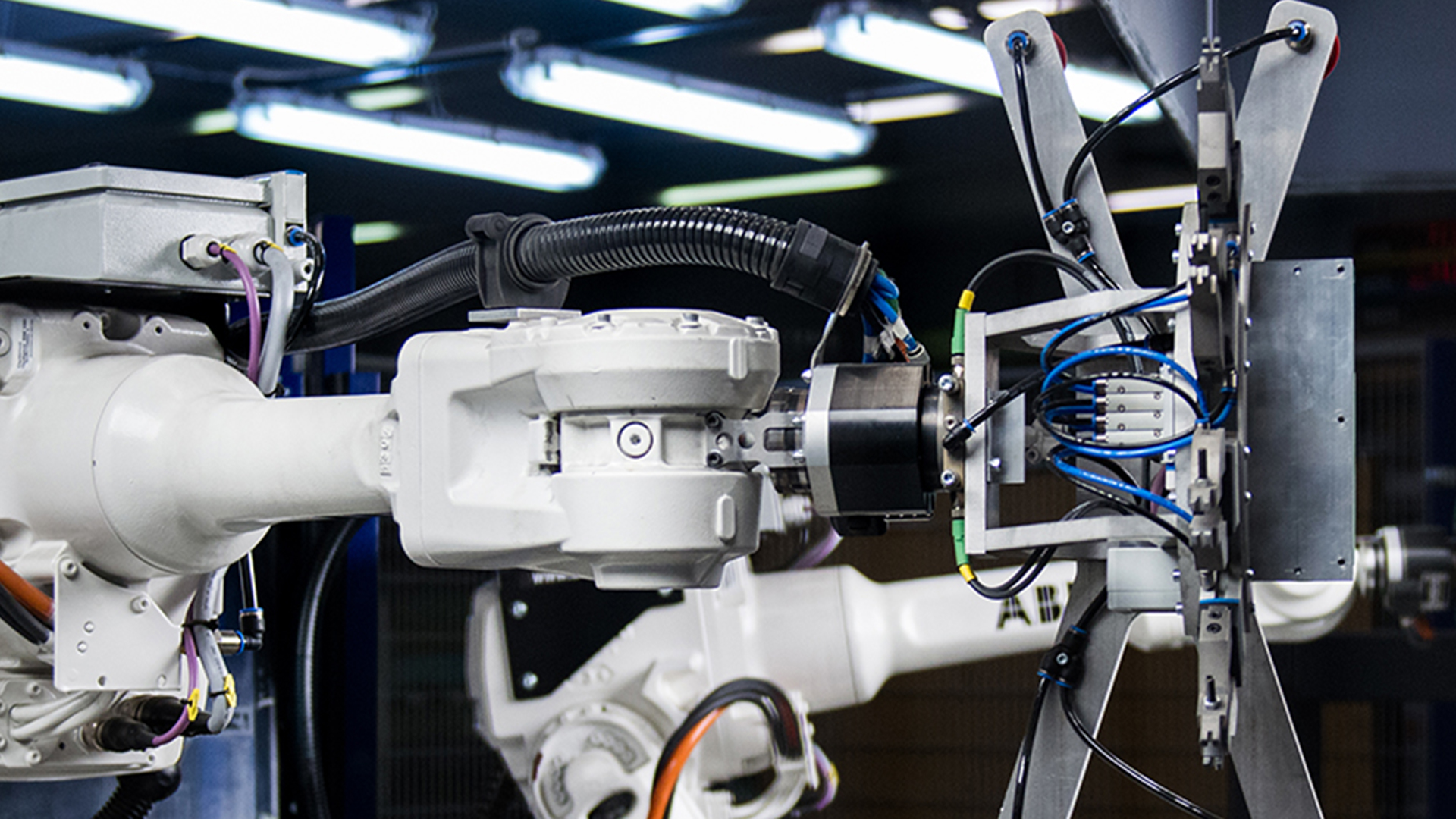

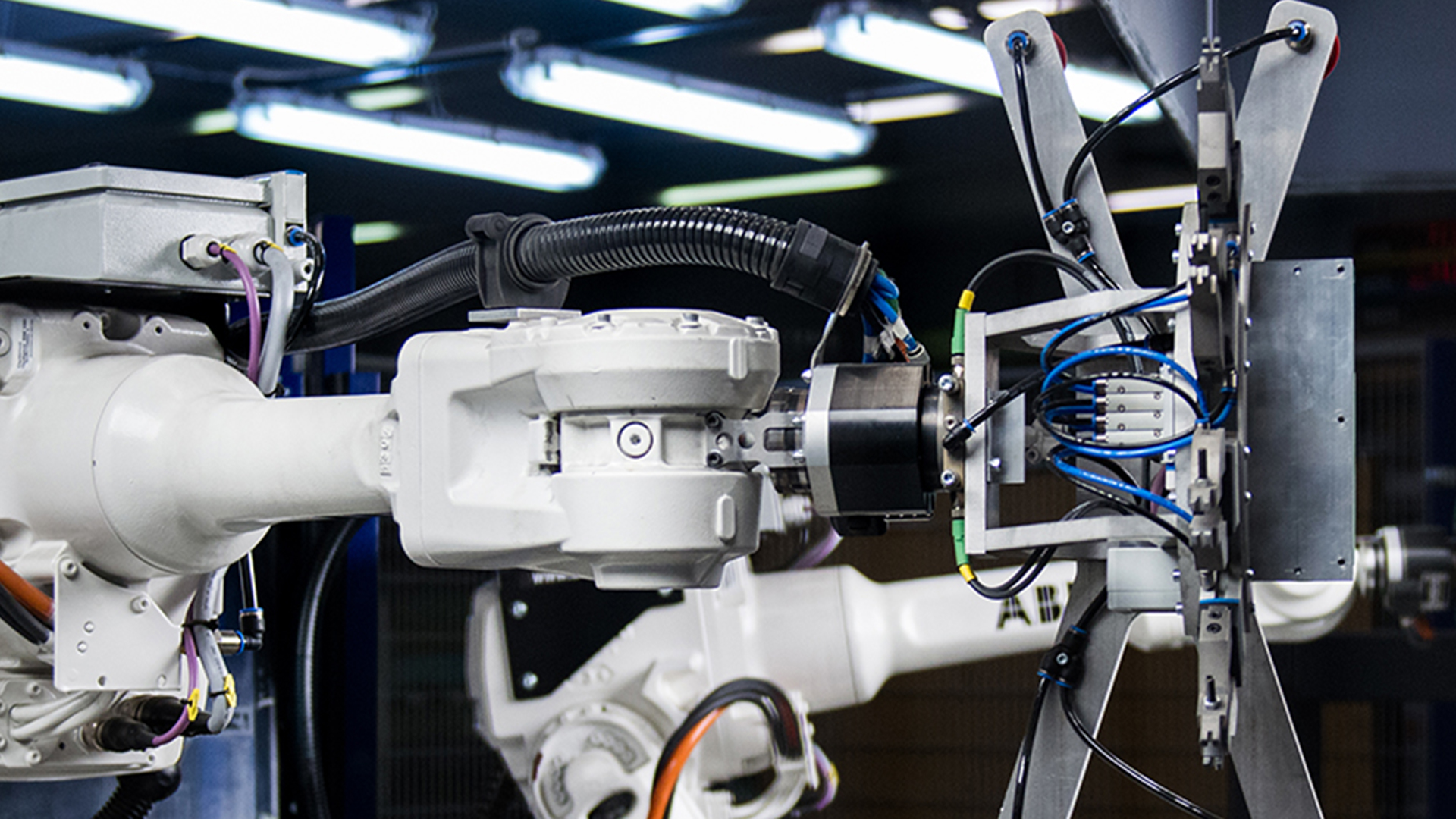

Post-processing such as milling/deburring of plastic or metal items is also used in the solutions we develop. The equipment/spindle is either mounted directly onto the robot or onto an external stand. By using such features as ABB’s “Force control”, it is possible to automatically adjust any machine tending according to the parts’s contours and shape while maintaining quality.